My church has a Klark-Teknik DN716 digital time delay that is part of the sound system. This is a microprocessor controlled three channel analog to digital (A/D) and digital to analog (D/A) converter with three independently adjustable delays. It isused to help control echo in the church by adding progressively longer time delays to the loudspeakers that are further from the front of the church. There are four pairs of speakers mounted on the ceiling support columns. The front pair are fed with no delay. The subsequent pairs are fed with a 22.1, 44.25 and 66.3 millisecond delays.

The "B" channel in this unit developed static as the unit warmed up. The sound system was installed in 1986 and this time delay is 26 years old.

Some time ago the unit developed a problem where the settings were not persistent on the next power up. I wrote to Klark-Teknik in the UK and they promptly responded with the information on the replacible internal battery along with a PDF file with the service manual and schematics!

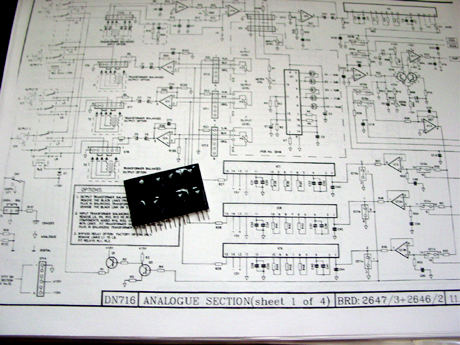

Now with this new static problem I wrote to them again. The service engineers at Klark-Technic were fabulous! Based on their experience they suspected the problem was with a defective filter module. This component is a thick-film hybrid 7-pole eliptical filter that is used to convert the digital signal into a smooth analog signal. The bad news is this part is $90! It's a custom part only made for them. The good news is they have them in stock and they are willing to sell one to me.

Can you imagine getting this kind of support after 26 years? I don't know of many companies who would sell a custom circuit board component to an end-user customer especially after so many years. It would have cost as much as $2,000 to replace this time delay unit today.

Before I started the repair work I turned on the sound system and let it warm up until I started hearing the static in the "B" channel. That way I could confirm a successful repair if I did not hear the static after a reasonable warm up after repair.

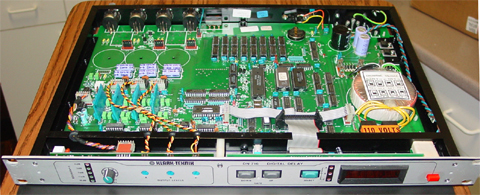

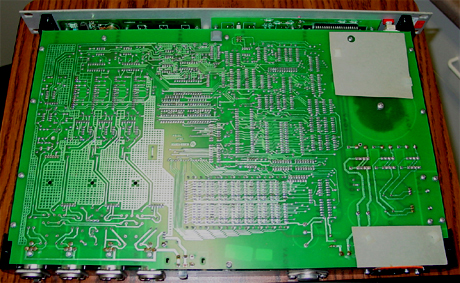

Here's the top view of the DN716. At first I thought I would have to remove the circuit board in order to unsolder the hybrid module. Then I realized all I had to do was remove the bottom cover!

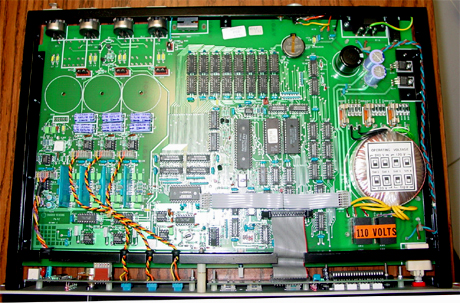

This is the bottom view. It's a service person's dream to have access to both sides of the circuit board by only removing the covers.

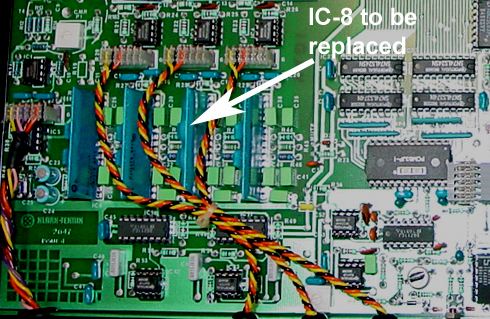

This is the part I need to replace. It is the hybrid filter IC8 part number SEM81-KTR009, Don't expect to find one of these in your local enectronics store.

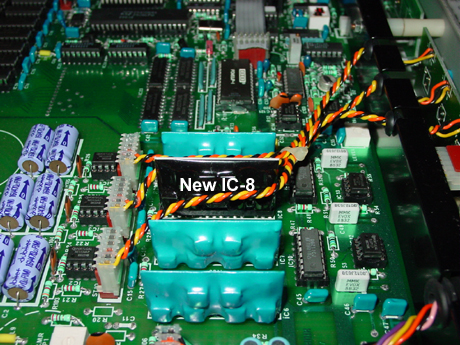

Here's a close-up view of the 4 hybrid filters. One is on the input. The other three are on each of the three output channels. Since I was having static on the "B" channel I replaced IC-8. It was fairly difficult unsoldering the filter. The holes were plated through. A solder sucker and solder wick were not very effective. I was on the verge of damaging the foil pads before I got all the leads to be free.

Instead of soldering the new module to the board I installed a socket. I made a socket by cutting a 40 pin dual inline socket making it into a 20 pin single inline socket. I soldered the socket to the board and plugged the new module into the socket. This way if anything happens in the future the module can be replaced without damaging the board.

I was so pleased to hear the unit come back to life. After waiting a reasonable length of time I was even more happy to hear not a single hint of static building after warm-up.

My deepest appreciation is extended to Andrew Shewring, technician at Music Group Research UK Limited for his expert advice and Eddie Roberts of Midas Consoles and Tina Dugas of American Music and Sound here in the US who sold me the part.